|

|

|

|

| Process Specialties is located just off highway 580 in the airport industrial area in Tracy California. We are in a 25,000 sq. ft. facility, a stones throw from the Tracy Municipal Airport, 15 minutes from Lawrence Livermore / Sandia National Labs, and a short 45-60 minute all-freeway drive from the greater Silicon Valley. We offer free daily pick-up and delivery services in the greater Silicon Valley Area. |

|

|

|

|

|

|

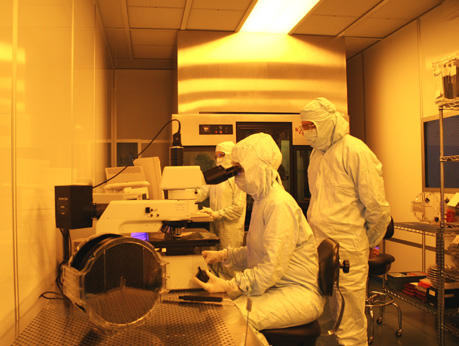

Clean Room One is a 3,000 square foot Class 100 / ISO 5 facility. It is well maintained and consistently over the years we have been able to achieve particle counts below class 100. Most visitors to our facility are impressed with how new the fab looks. Over the years we have modified and upgraded both the facility and its equipment to meet our clients changing processing needs. In the 30 years since it's completion this clean room and the Engineers and Technicians that work in it have successfully processed millions of 75mm- 300mm wafers. |

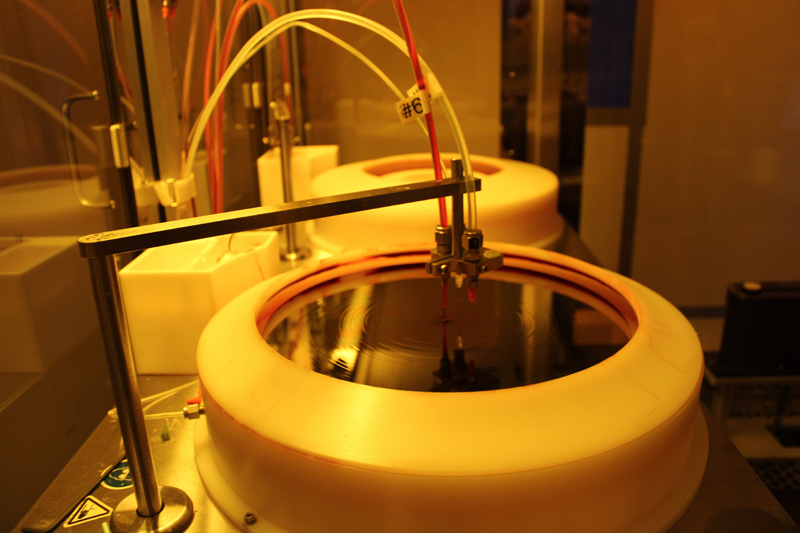

Photolithography areas in Clean Room One

|

|

All wafers are tracked and logged through every step in the process using bar code scanners and a computerized logging system. |

New 300mm diffusion furnace load station in Clean Room One Note: all the diffusion furnaces at Process Specialties are cantilever load and auto push pull. This means low particle thin films and no warped wafers. |

|

|

In this clean room we have an additional 2,200 square feet of Class 10 / ISO 3 Clean room space dedicated to 200mm & 300mm processing.

Here in the Clean Room Two Photolithography area we see the Saturn 300, capable of 150mm-300mm lithography on resist up to 10um thick. |

|

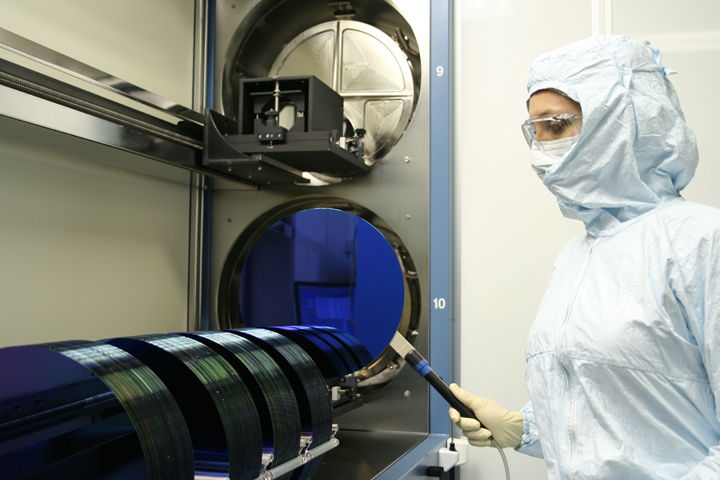

The unloading of 300mm wafers after oxidation We commonly see uniformities of 1% or less across the wafers (furnace prime), as well as no detectable flatness changes or diffusion related slip has been found on our 300mm Oxidized wafers. |

Currently in our 300mm diffusion tools we are running multiple Thermal Oxide, Polysilicon and LPCVD Nitride systems for 300mm wafers. This means we can out produce any of our competitors on these key thin films. This translates into faster 300mm turn times for our customers. |

Accuracy in metrology is never an issue At Process Specialties. We use advanced robotic laser ellipsometers and other calibrated tools for precision thin film, resistivity, CD and step height measurement. In 2005 with the introduction of our Calibration Standards product line PSI Standards, our thin films truly are the industry standard. |

In this clean room we have an another 2,500 square feet of Class 10 / ISO 3 Clean room space dedicated to 200mm & 300mm processing. This clean room area increased our 300mm & 200mm processing capabilities including more PVD Metalization, 300mm Wet processing and 300mm stepped Photolithography, all in a Class 10 environment. In 2023 Process Specialties continues to have more "in-house" 300mm processing capacity than nearly all of its competitors. This translates into Faster Turn Times for our customers custom processing needs. | ||

Views of the Clean Room Three Lithography area In this area we have a 300mm I-Line stepper, 300mm resist track, and a 300mm wafer inspection system

| ||

Two of our 300mm PVD metal tools in the Clean room 3 PVD area. These tools are also capable of processing 100mm,150mm and 200mm wafers. | ||

Views of the wet clean area in Clean Room Three

Last a view of the rear facilities area of

Clean Room Three. Here you can see the waste water treatment system, DI water system and other support equipment for the Clean room. |

||

| Remember, to get a complete tour of this facility you must visit Process Specialties in

person. This public tour just shows some of the highlights of our Fab areas, just enough to make our remote customers who don't have a chance to visit, feel comfortable in knowing their wafers are being processed in a clean―First Class facility.

To arrange a tour of Process Specialties, call PSI customer service @ 1.800.533.8820 Toll Free in USA Note: To visit us, your company must be a current customer of Process Specialties, Inc.

|

| CONTACT PSI | © 1996-2023 Process Specialties Inc., all rights reserved |